PETRO-BARRIER

Designed for the largest volume of water drainage in a good drainage field with a vertical type installation, Petro-Barriers™ are custom-designed and manufactured in our factory and delivered to your facility / facilities. Land slope, under-drain percolation rates, rainfall amount, containment area size and other factors are all considered in the system design. Large containment areas or installations in wet climates might require six or more sumps whereas a small area in a low-rainfall climate might need only one or two Petro-Barriers™. Because of this variability, our customers rely on our extensive experience to design the optimum spill containment system.

In a spill containment area surrounding an oil storage vessel or oil-filled electrical transformer, everything on the ground is designed and created to be impervious to oil and water. The ground is sloped to drainage sumps where the Petro-Barriers™ will be installed. After the drainage path and spill containment area have been completed, SPI fills the drainage sumps with three types of media that allow water to pass while removing and locking up any oil.

Average stormwater drain rates per barrier vary from 4000 litres /Hr with the 450mm diameter Petro-Barrier™ to more than 11,000 Litres /Hr with the 900mm diameter Petro-Barrier™. Petro-Barriers™ are typically 600mm deep, though custom applications are available. The most popular diameters are 450, 600 and 900mm.

Why use Petro-Barrier?

Flow rates up to 11,000L per Hr

Petro-Barriers™ cost less to install, require virtually no maintenance under most circumstances, and offer the most foolproof way to prevent oil from being discharged along with storm water.

HOW DOES AN SPI

PETRO-BARRIER WORK?

Expensive, high-maintenance methods such as oil/water separators, oil stop valves and oil sensing switches for pumps have contributed to or failed to prevent significant and costly oil spills for many of our customers. In comparison, with thousands of installations, oil has never gotten past the Petro-Barrier™.

Petro-Barriers™ cost less to install, require virtually no maintenance under most circumstances, and offer the most foolproof way to prevent oil from being discharged along with storm water..

In a spill containment area surrounding an oil storage vessel or oil-filled electrical transformer, everything on the ground is designed and created to be impervious to oil and water. The ground is sloped to drainage sumps where the Petro-Barriers will be installed.

After the drainage path and spill containment area have been completed, SPI fills the drainage sumps with three types of media that allow water to pass while removing and locking up any oil. Average stormwater drain rates per barrier vary from 4000L per Hour (LPH) with the 450mm diameter Petro-Barrier to more than 22200LPH with the 1828mm diameter Petro-Barrier.

TRANSFORMER OIL

CONTAINMENT AREAS

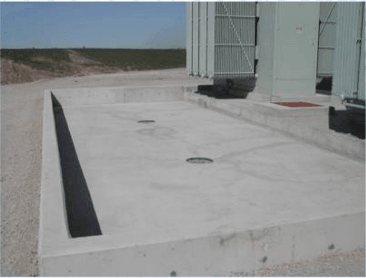

In this new substation, a moat containment area surrounds the transformer. Petro-barriers are used to drain rainwater and provide 100% oil containment.

This drawing shows a Petro-Barrier draining rainwater from the surface of the oil containment area. It is similar to the first drawing, but a perforated drainpipe has been installed under the Petro-Barrier and is surrounded with crushed stone, allowing the rainwater to drain and dissipate into the ground.

This design allows for better drainage in poorly draining clay-like soils.

Note: All surfaces slope towards the barrier drains for proper stormwater discharge. The contractor is to prepare the area as shown and provide drainage holes for barriers. Containment area sized to hold the full contents of the transformer plus 10%-25% rainwater as required.

CONCRETE MOAT SYSTEM FOR

OIL CONTAINMENT

Figure 1 and Figure 2 display a concrete moat system for oil containment. There are many different ways to configure the moats and Petro-Barrier locations.

In this drawing, there are four Petro-Barriers, one in each corner, with steel grates above affording a level work surface around the transformer.

The design can also incorporate crushed stone in the containment pit with access to each Petro-Barrier.

SPI top hat filters are used with the Petro-Barriers for extra dirt and debris protection inside containment areas. The top hat filters attach to the top of the Petro-Barriers and utilize replaceable dirt and debris filters that greatly increase the useful life of the Petro-Barrier media.

NEED PETRO-BARRIERS?

GET PREFAB PETRO-BARRIERS

SENT DIRECTLY TO YOU

Prefabricated Petro-Barriers are sent directly from the SPI factory to your facility for installation. They are made to discharge directly into the ground, or we can add a lateral discharge to a dry well or daylight, either one.

There are 3 common Petro-Barrier sizes, PB-450, 600 ,900mm. The different media work together to provide 100% oil spill protection and non-detectable oil levels in the discharge.

FLEXIBLE PETRO-BARRIER INSTALLATIONS

The lower drawing shows the Petro-Barrier installed outside the oil containment area. All water and potential oil is piped to a remote Petro-Barrier. The Petro-Barrier drains all rainwater as needed, and completely shuts down to provide 100% containment in the event of an oil spill.

PETRO-BARRIER INSTALLATION

WITH CONTAINMENT LINER

This is a diagram of a Petro-Barrier installed through a containment liner providing rainwater drainage and oil spill containment. A flange is installed between the top of the liner and the HDPE Petro-Barrier housing and is then backfilled with crushed stone and dirt.

The liner is set in place on the floor of the containment area, and the 914mm perforated access pipe is attached to the flange on the Petro-Barrier housing. The access pipe is then backfilled with clean crushed stone, so when it rains, the water will enter the access pipe through the perforations and drain through the Petro-Barrier. When all construction is complete, the Petro-Barrier cartridge is then lowered into the access pipe and the housing pipe below the liner. It is then attached with screws, and additional dirt filters are installed. A steel grate is installed to provide access from the top for maintenance and change-outs.

HOW DOES THE PETRO-BARRIER COMPARE TO THE COMPETITION?

Expensive, high-maintenance methods such as oil/water separators, oil stop valves, and oil sensing switches for pumps have contributed to or failed to prevent significant and costly oil spills for many of our customers. In comparison, with thousands of installations, oil has never gotten past the Petro-Barrier.

Petro-Barriers cost less to install, require virtually no maintenance under most circumstances, and offer the most foolproof way to prevent oil from being discharged along with stormwater.